Answer

May 02, 2024 - 03:59 AM

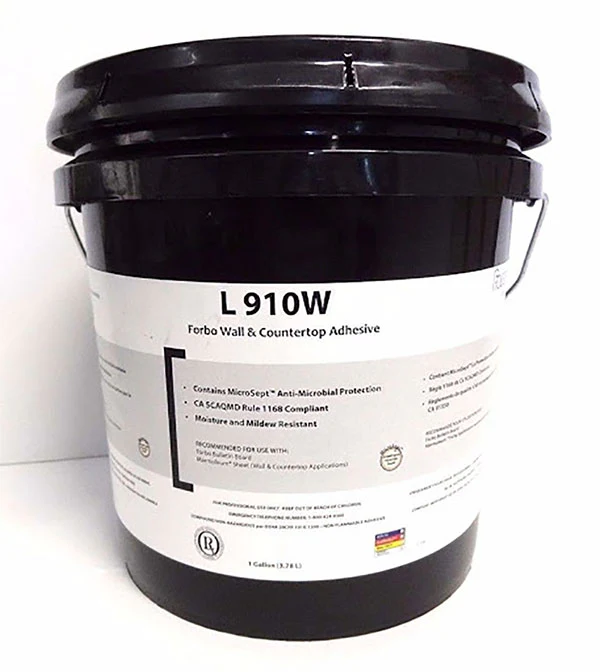

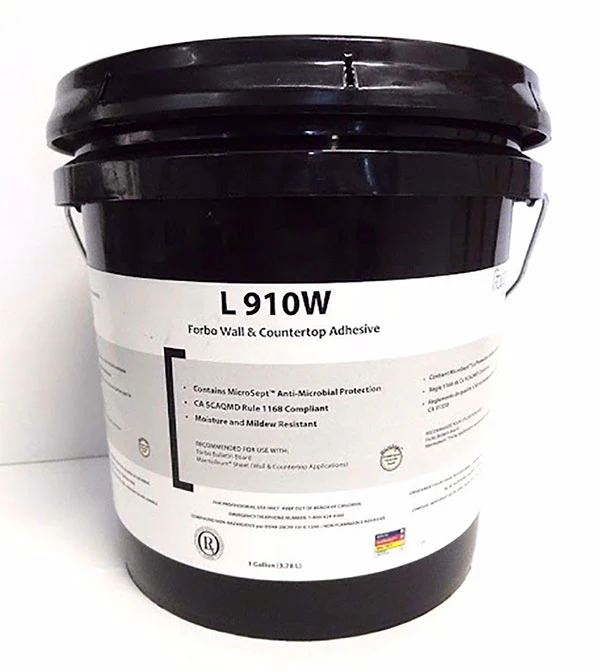

Per the installation instructions https://www.greenbuildingsupply.com/core/media/media.nl?id=2412273&c=772072&h=8

W9CzQCmOONfnFJJAwYF4aOha8mP9mEx_4nKhHgFgE5BSwMI&_xt=.pdf , " . The adhesive should be allowed to develop body before placing the material into the adhesive, but DO NOT ALLOW THE ADHESIVE TO DRY. The material MUST always be placed into wet adhesive androlled immediately. The material must also remain in contact with the adhesive while the adhesive is drying and curing. In order to ensure continuous contact of the material and the adhesive, the natural �roll curl� at the end of each cut should be relaxed, or massaged, both before and during the installation process, to remove the tension caused by being rolled. Adequate relaxing should enable the material to remain in contact with the adhesive. "

W9CzQCmOONfnFJJAwYF4aOha8mP9mEx_4nKhHgFgE5BSwMI&_xt=.pdf , " . The adhesive should be allowed to develop body before placing the material into the adhesive, but DO NOT ALLOW THE ADHESIVE TO DRY. The material MUST always be placed into wet adhesive androlled immediately. The material must also remain in contact with the adhesive while the adhesive is drying and curing. In order to ensure continuous contact of the material and the adhesive, the natural �roll curl� at the end of each cut should be relaxed, or massaged, both before and during the installation process, to remove the tension caused by being rolled. Adequate relaxing should enable the material to remain in contact with the adhesive. "