Answer

Jul 22, 2025 - 02:50 AM

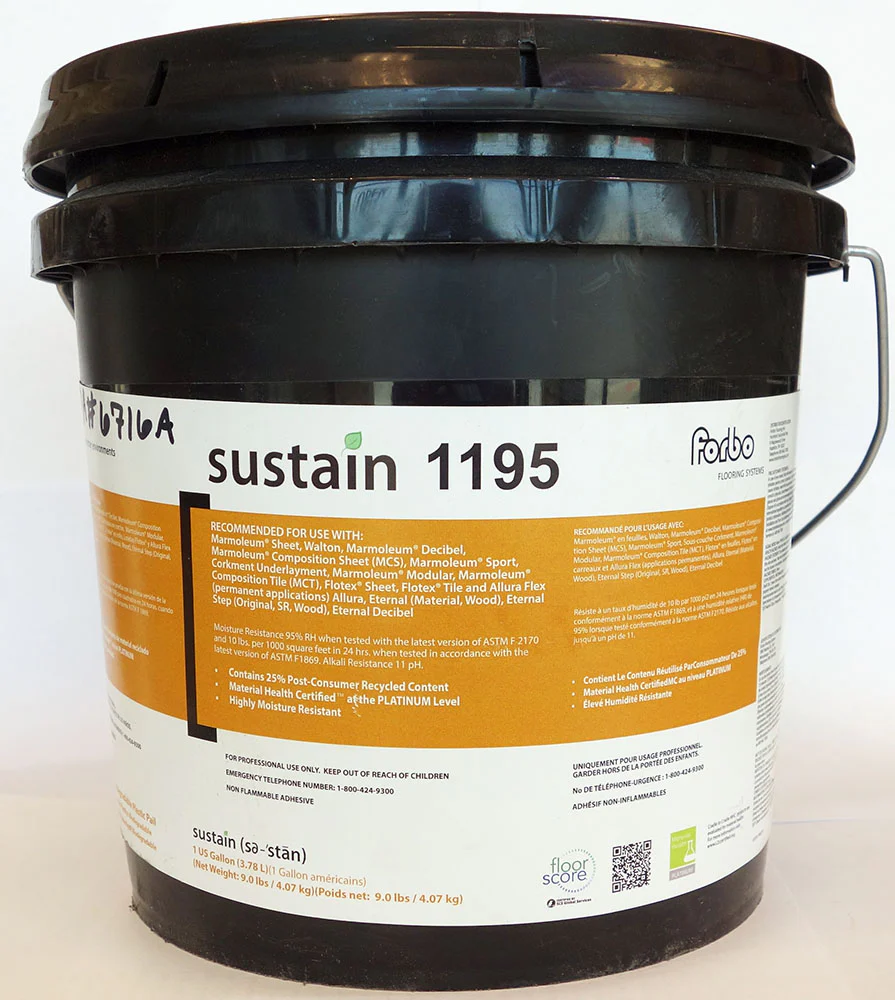

Quoting the Application instructions here:https://www.greenbuildingsupply.com/cdn/shop/files/Doc-Forbo-Sustain-1195-Marmo

leum-Sheet-And-Tile-Adhesive_Tech-Data_Sheet_SPEC_2015_GreenBuildingSupply.pdf?

v=9116163132127184165"MARMOLEUM� SHEET: Install one sheet at a time. The adhesive should be allowed to develop body before placing the flooring material into the adhesive, but DO NOT ALLOW THE ADHESIVE TO DRY. The flooring material MUST always be placed into wet adhesive and rolled immediately. The flooring material must also remain in contact with the adhesive while the adhesive is drying and curing. In order to ensure continuous contact of the material and the adhesive, the natural �roll curl� at the end of each cut of Marmoleum� should be relaxed, or massaged, both before and during the installation process, to remove the tension caused by being rolled. Adequate relaxing should enable the material to remain in contact with the adhesive but, if necessary, weight should be applied to ensure that the flooring material remains in full contact with the adhesive while the adhesive is drying. Proper sheet placement and rolling will appear as clearly defined transfer marks that can be seen on both the substrate and material backing. " That highlights that it should not be allowed to dry first.

leum-Sheet-And-Tile-Adhesive_Tech-Data_Sheet_SPEC_2015_GreenBuildingSupply.pdf?

v=9116163132127184165"MARMOLEUM� SHEET: Install one sheet at a time. The adhesive should be allowed to develop body before placing the flooring material into the adhesive, but DO NOT ALLOW THE ADHESIVE TO DRY. The flooring material MUST always be placed into wet adhesive and rolled immediately. The flooring material must also remain in contact with the adhesive while the adhesive is drying and curing. In order to ensure continuous contact of the material and the adhesive, the natural �roll curl� at the end of each cut of Marmoleum� should be relaxed, or massaged, both before and during the installation process, to remove the tension caused by being rolled. Adequate relaxing should enable the material to remain in contact with the adhesive but, if necessary, weight should be applied to ensure that the flooring material remains in full contact with the adhesive while the adhesive is drying. Proper sheet placement and rolling will appear as clearly defined transfer marks that can be seen on both the substrate and material backing. " That highlights that it should not be allowed to dry first.