Gulf Synthetics DeckRevive

Item #25179

Model #GSDR 5.0

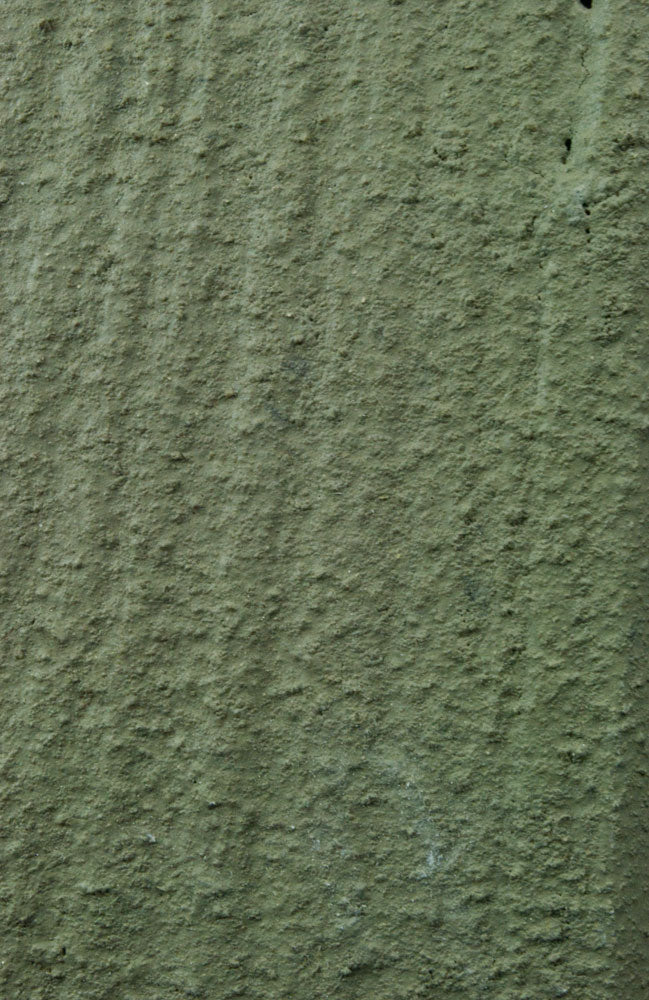

Do-it-yourself, highly durable protective coating

Gulf Synthetics' DeckRevive is a non-toxic, water-based coating that cross-links with exterior paint to form a hard, durable covering that protects any wood substrate. Simply mix it with one-gallon of colored gloss sheen exterior paint to rejuvenate old worn out, dried out, beat up decks, fences, siding, furniture or anything made of wood (NOT for use on composite decking).

NOTE: We recommend ECOS Interior Wall and Ceiling Paint as the mixer. It sounds counterintuitive, but the Gloss Sheen of this interior paint is endorsed for exterior and interior usage.

DeckRevive is a two-part additive, with one part powder and one part liquid. It comes with a five-gallon bucket for easy and convenient mixing. With two coats applied, the coverage will be approximately 200 square feet per kit depending on surface porosity and texture.

PLEASE NOTE: For proper adhesion, PermaBond is REQUIRED as a primer for this product.

NOTE: Permafill (for deep holes and cracks) has been discontinued, Gulf Synthetics recommends Quikrete Quick Setting Filler as a replacement for Permafill.

Why We Like It

If you believe in miracles, this product is up for nomination. It's truly a deck and dock saver. It transforms old decks, docks, fences, etc., into like-new beautiful skid-resistant surfaces that will last a very long time. No reapplication or touch-up necessary.

Features & benefits

- Easy-to-use – DIY; mix and paint with two coats

- Fast-drying – dry to touch in minutes; open to foot traffic in a few hours

- Multi-purpose – use on decks, docks, siding, shakes, hand rails and furniture

- Long-lasting – resistant to stains, scuffs, skid marks and fire; no or low maintenance required

- Helps inhibit rust – stops bleed-through from nails and fasteners

- Encapsulates wood – locks down splinters; fills holes

- Unlimited color range – just add any color gloss sheen exterior latex or acrylic paint

- Non-toxic – to human or aquatic life

- Safe — for everyone, including the chemically sensitive; learn how to test a non-toxic product for tolerance

- Eco-friendly – zero VOC

DISCONTINUED SIZES: Quarter Kits

NOTE: Please note it may take several test runs to get just the right color.

Specs

Columns

Decking

Decking: old

Docks

Fences

Shingles

Siding

Wood: all types

CLEAN: Surfaces must be thoroughly clean, free of dirt, sealer or waxes, peeling paint, mildew, tar, mill glaze, efflorescence, grease or oily substances. Clean the surface by power washing, and allow substrate to dry completely for a minimum of 48 hours. Do not use a Deck cleaning product because many contain solvents. (DO NOT use a detergent with a de-greaser)

DRY: The surface needs to be thoroughly dry. Test wood using a probe type moisture meter. No more than a 20% moisture content is recommended. For exterior projects, do not apply if precipitation is predicted in the next 24 hours.

DULL: Glossy, painted, or sealed surfaces must be dulled by sanding, to produce a profile for the DeckRevive™ coating to bond to. After sanding, clean surface of any loose debris.

MODERATE TEMPERATURE: For best results apply between 40˚- 85°F. Do not apply if ambient temperature or the surface temperature is <40˚ or >85˚F. If temperature is less than 40˚F this product will cure too slowly or maybe not at all. If temperatures exceed 85˚F, this coating may set too quickly. Additionally, do not apply coating if temperature is predicted to drop below 40˚F within the next 24 hours.

PREPPING CRACKS AND NAIL/SCREW HEADS: DeckRevive™ is quite thick and will easily fill most small cracks. If existing cracks are excessive (over 3/8” deep and wide) use Quikrete Quick Setting Filler to infill before coating with DeckRevive™. For best results, countersink rusting nail or screw heads and apply Quikrete Quick Setting Filler to infill. Do not smear Quikrete Quick Setting Filler on adjacent wood surface. Allow Quikrete Quick Setting Filler to dry 2-hours before applying DeckRevive™. If you desire, rusty nails can be spot primed with a rust inhibitive primer found at your local paint store. See manufacturers recommended rust inhibitive primer specification sheet.

PRIMER REQUIRED: PermaBond Primer is required over pre-painted, pre-stained, redwood, cedar and extremely cracked or weathered deck boards when applying DeckRevive. PermaBond can be colored by adding 1 quart of exterior latex paint to a gallon of PermaBond.

PREP: Remove both wet and dry chemistry from container. Empty the white liquid resin into container. Add one gallon of exterior latex or acrylic GLOSS paint (any color) NOTE: This will not work with a non-gloss paint. Mix briskly for one minute.

Slowly add dry chemistry while stirring briskly with drill mixer for five minutes. Stir mixture to loosen up any dry portion from the bottom of container. Dry chemistry components should break down completely and mix should be smooth and viscous before using.

The coating is now activated and should be used immediately.

Do not alter the chemistry of the product in any way by adding or subtracting material or by adding other ingredients (DO NOT ADD WATER). If you are working on a large area with more than one kit, mix each kit separately and then blend together for color consistency.

APPLICATION: For best coverage, use a 3/8" nap paint roller and roll out the first coat perpendicular (against) the grain. This allows the coating to work into the cracks and splinters, filling them up and locking them down.

Allow the first coat to dry completely before applying the second coat.

Apply second coat in the opposite direction or parallel with the grain of the wood. The second coat is the key to attaining the proper texture.

If a more aggressive non-slip texture is desired, use a one-inch nap roller for the second coat. Be consistent in your technique. Allow second coat to dry.

Additional coats may be applied to build upon the final mil thickness, if desired.

CLEAN-UP: Clean tools with water. Buckets should be cleaned and re-used.

STORAGE: Keep a lid on any extra product and store in a cool, dark and dry space. Activated coatings will have an approximate 14-day pot life.

Download "Application Instructions" document for complete instructions.

- Paint

- Sealer

Questions & Answers