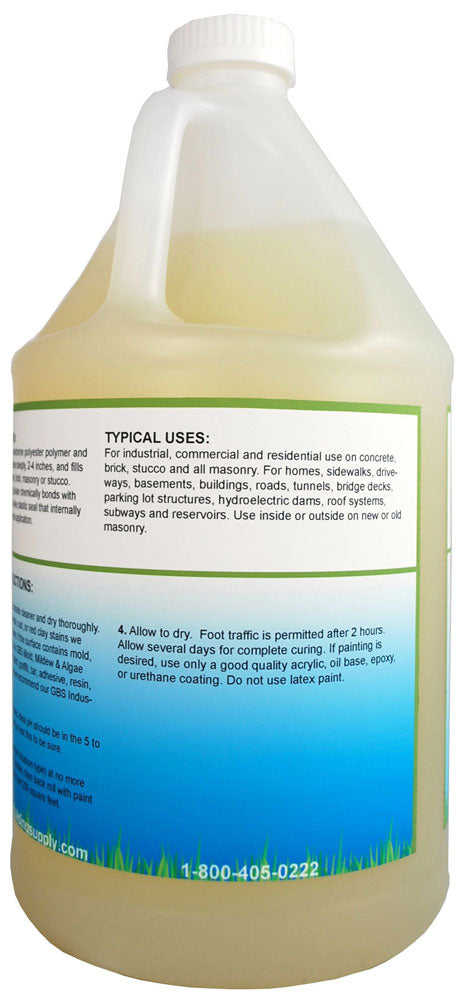

Green Building Supply, Penetrating Concrete Sealer

Item #3576

Model ##60-66 5G Clear

Safe, permanent waterproofing sealer for concrete, masonry, stucco or brick

Cold Weather Alert

This product may not perform properly if applied below the required temperature. Please check installation instructions on our website. Because this is a water-based product, it may freeze during shipping. For that reason we will not ship over a weekend if temperatures dip below 32 degrees F. If you want us to ship anyway, it will be at your own risk. Please call to arrange with a GBS eco-advisor. 888.727.2101GBS Penetrating Sealer is a waterborne polyester polymer and polyurethane that works best on concrete, brick, stucco and masonry. It waterproofs and preserves with 3-5 coats, plus it comes with a 15-year waterproofing warranty. Unlike topical sealers that sit on the surface and rub off with wear and tear, GBS Penetrating Sealer protects from inside the material where it can't wear away. In other words, this sealer actually becomes part of the substrate.

This sealer penetrates two to four inches deep, filling molecular voids to completely solidify the entire structure. When it dries, it becomes part of the structure creating a solid matrix. This means there's no room left for water to infiltrate and leak through. In addition, the substrate becomes stronger and lasts longer.

Dry time for indoors is apx. five days; outdoors 2-4 days depending upon temp and humidity. Allow 48 hours before walking on. Avoid using it before rain.

GBS Penetrating Sealer is solvent-free, odorless, non-flammable, non-caustic, and almost no VOC (5.9 g/l). Use it on basement walls and floors, retaining walls, pool surrounds, brick veneer walls, chimneys, fireplaces, concrete or limestone pavers, driveways, sidewalks, patios, warehouse floors, and historical renovations.

Quality Control Test results: GBS Penetrating Concrete Sealer has passed 9 independently performed quality tests per the HRP specifications. These tests include:

- ASTM 413 - “Water Absorption of Chemical Resistant Concrete/Masonry”

- ASTM C140 - “Masonry Absorption Test for Light Weight Block”. ASTM requires that water absorption cannot exceed 1% after 2 days of immersion.

- ASTM 123D - “Penetration Test for Nuclear Power Plant, 8000 psi Concrete Pour”

- Blue Dye Test - “Blue Dye Absorption Test”

- ASTM 642-82 - “Masonry Absorption Test for Brick”

- ASTM C672 - “Scaling Resistance”

- AS 1012.21-1999 - "Water Absorption of Hardened Concrete"

- NCHRP 244 – Cube Test – “Accelerated Weathering Test”

- NCHRP 244 – Southern Exposure – “Chloride Ion Penetration Test”

- Porous

- Clean

- Free of any other sealers, coatings, stamped concrete release agents

- Neutral pH — between seven and nine

- Dry

NOTE 1: GBS Penetrating Sealer should NOT be used in areas constantly under water such as cisterns. Also, any areas that have been power troweled, especially in basements, need to be acid etched or mechanically ground before application in order to open the pores. This product should not be used on stamped concrete.

NOTE 2: Do not use this product in working fireplaces as it is not suited to that kind of heat (may bubble and melt).

NOTE 3: If you plan on applying ceramic or porcelain tile to the surface at some point in the future, do not use this product. It will seal the concrete so well that the thinset will not adhere to the surface—unless, of course, it is etched or ground.

NOTE 4: This product will only perform well if applied correctly. Be sure to read and follow the application instructions.For proper adhesion, the surface must be:

Please see the application instructions for details on each of the above steps.

NOTE 5: You can paint over this product with a 100% acrylic concrete floor paint. We recommend AFM SafeCoat Concrete Floor Paint.

A similar product, GBS Penetrating Gloss Sealer, provides a low-gloss finish.

Why We Like It

Whether you want to stop your basement walls or floors from leaking, or just want to prevent deterioration of your mortar in a brick wall, this is the right product for the job. It's a smart way to prevent problems before they arise. An inexpensive insurance policy.

Features & benefits

- Permanent waterproofing — becomes part of your material; 15-year warranty against water intrusion

- Superior durable finish — penetrates in; can't rub off; protects against freeze-thaw

- Strengthens substrate — extends material life; reduces efflorescence and concrete dusting

- Easy-to-use — sprays on; no mixing required; water cleanup; pH strips provided

- Non-toxic — no formaldehyde, ammonia, crystalline silica, ethylene glycol, mildewcides, fungicides, exempt solvents or aromatic hydrocarbons commonly used in sealers

- Safe — for everyone, including the chemically sensitive; learn how to test a non-toxic product for tolerance

- Eco-friendly — almost no VOC (5.9 g/l)

ALERT: This product will only perform well if applied correctly. Be sure to read and follow the application instructions. Test first to see how it affects your specific application.

Specs for

5-Gallon

5-Gallon

Brick

Concrete

Concrete: unsealed

Masonry: unsealed

Stone

Stucco

Tile: unglazed

1) Porous

2) Clean

3) Dry

4) Neutral pH

Porous means it should be able to soak in. If there are sealers or adhesives on the surface they will disallow absorption. If the surface has been highly power-troweled it will also make the surface so dense that water will not soak in easily.

How to Test? Place a few drops of water onto the surface and see if it beads up or soaks in. If it soaks in, then the surface is porous and GBS Penetrating Sealer will also soak in. Nothing need be done except to make sure it is clean, dry and have a neutral pH. See #2 and #3 below.

If, however it beads up and does not soak in for about an hour, then there is either something on the surface or it has been power-troweled.

If powertroweled, use our GBS MicroEtch product to open the pores without toxic chemicals.

Roller

Sponge

Spray is best

Test BEFORE applying. Power-troweled surfaces may not absorb well and should be etched with our Micro-Etch. Apply in good weather when air and surface temperature are above 45°F. and surface temperature is at least 5°F. above the Dew Point. For optimum application properties, materials should be between 70-90°F prior to application.

1. Use a low pressure sprayer (Hudson type) or any sprayer operated at no more than 20 psi. Spray on with low-pressure sprayer and back roll using a 3/8 inch nap roller any puddles into a dry area with a low nap paint roller. The goal is to saturate the surface. This may require 3-5 passes, one after the other, WET ON WET application.

Note: If the concrete was power troweled, GBS Penetrating Sealer may not absorb at all. Using our MicroEtch product will open the pores and allow for proper penetration. One gallon of GBS Penetrating Sealer covers approximately 200 square feet depending upon porosity.

2. Ideally you will work with two people. One spraying and one using a 3/8 inch nap paint roller to spread out excess (do not allow excess puddles to dry as results could be slippery). Clean the roller or brush with soap and water.

3. Allow to dry thoroughly before traffic is allowed onto the floor

indoors approx 5 days, outdoors 24-48 hours depending upon temp, humidity, and air flow

avoid using before rain.

4. 6 to 7 days for completion of penetration/curing process.

5. If you are using GBS Penetrating Sealer before painting, allow-dry a minimum of three days prior to the application of paint. GBS Penetrating Sealer will waterproof the surface so well that non-moisture resistant paints (such as but not limited to latex) should NOT be used. Use only good quality moisture-resistant paint such as 100% acrylic or oil-based paint. We recommend AFM SafeCoat Concrete Floor Paint.

Note: GBS Penetrating Sealer will not harm glass, aluminum, metal, plants or aquatic life. If GBS Penetrating Sealer gets on glass, rinse off so it doesn't dry. Not recommended for painted stucco (unpainted is fine) and submerged areas in pools or ponds. Not for use in working fireplaces.

- Sealer

Questions & Answers